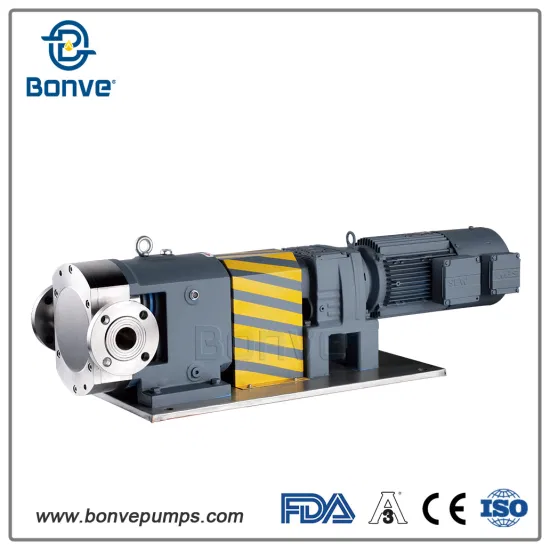

Ammonium Nitrate Transfer Pump Rotary Lobe Pump Rotary Pump Positive Displacement Pump High Viscosity Liquid Transfer Pump

Basic Info.

| Installation Type | Fixed, Mobile |

| Pressure | 0-1.2MPa |

| Flow Range | Upto 400m3/H |

| Connection Type | Flange, Clamp, Thread, |

| Port Size | 1inch-16inch |

| Brand | Bonve Pump |

| Pump Type | Positive Displacement Pump |

| Transport Package | Plywood Case |

| HS Code | 841360 |

| Production Capacity | 50000sets/Year |

Product Description

Ammonium nitrate transfer pump rotary lobe pump rotary pump positive displacement pump high viscosity liquid transfer pump

To comply with the environmental requirements, customers have higher request to the pump used for ammonium nitrate applications. The pump should have no leakage during operation. So pump seal device should be reliable. Bonve is committed to using the latest and innovative technology to improve the pump performance and the seal reliability, thereby helping customers improve production efficiency and ensure safety. Bonve rotary lobe pumps are especially suitable for transferring chemical products with high viscosity, high solid and strong corrosion in the chemical industry.Typical mediums transferred: Resin, adhesive, polyurethane, dye, pigment, various intermediates, various slurries, chemical additives, printing and dyeing additives, leather additives, silicone oil, bio-oil, leather shoe polish, suspension, white latex, etc.

Bonve rotary lobe pumps are designed based on the exploration of more than 3,000 fluids in various industries. They are particularly pumping for high viscosity, high solids, sanitary and corrosive fluids. The pumps are widely used and have long service life benefits from the below features.1. Interchangeable rotors, multi connection type and installation type, fit for various applications.2. Targeted seal for specific application, ensure a reliable sealing.3. Compact structure, easy assembling and disassembling.4. Maintenance in place (above the models of 80BV), easy cleaning, CIPable and SIPable.5. Few wearing parts, low maintenance.6. All main parts proceed by CNC, high precision fabrication.7. No contact between the rotors, rotors and pump chamber.8. Multi bearings with separate arrangement, high pressure resistance. 9. Axis key synchronous adjustment, no rotor collision problem.10. The flow can be controlled at will by frequnecy inverter.11. Capable to pump the viscous medium from 1cp to 2million cps. 12. Capable of pumping mixture of gas, fluid and solid medium.

Bare shaft pumps with different rotorsComplete unit pumps

Product Parameters| Model | Displacement | RPM | Flow | Dis. Pre. | Power | Suc. Pre. | Port size | |

| (L/r) | (r/min) | (M³/h) | (Mpa) | (Kw) | (Mpa) | Std. (mm) | Enlar. (mm) | |

| 40BV12-2 | 0.15 | 10-1000 | 0-2 | 0-0.6 | 0.75-2.2 | -0.080 | 25 | 40 |

| 50BV12-5 | 0.32 | 10-800 | 0-5 | 0-0.7 | 1.5-4 | -0.095 | 40 | 50 |

| 65BV12-10 | 0.65 | 10-600 | 0-10 | 0-1.0 | 2.2-7.5 | -0.085 | 50 | 65 |

| 80BV12-20 | 1.74 | 10-500 | 0-20 | 0-1.2 | 4-15 | -0.085 | 65 | 80 |

| 90BV12-30 | 2.48 | 10-500 | 0-30 | 0-0.8 | 5.5-22 | -0.095 | 80 | 100 |

| 100BV12-40 | 3.65 | 10-500 | 0-40 | 0-1.2 | 7.5-30 | -0.095 | 80 | 100 |

| 125BV12-50 | 4.60 | 10-500 | 0-50 | 0-0.8 | 7.5-37 | -0.095 | 100 | 125 |

| 140BV12-70 | 6.10 | 10-500 | 0-70 | 0-1.2 | 11-45 | -0.095 | 125 | 150 |

| 150BV12-80 | 7.63 | 10-500 | 0-80 | 0-1.2 | 11-55 | -0.095 | 125 | 150 |

| 200BV12-120 | 11.56 | 10-400 | 0-120 | 0-1.2 | 15-75 | -0.095 | 150 | 200 |

| 250BV12-150 | 14.22 | 10-400 | 0-150 | 0-1.2 | 18.5-90 | -0.095 | 150 | 250 |

| 300BV12-200 | 20.80 | 10-300 | 0-200 | 0-1.2 | 22-110 | -0.095 | 200 | 300 |

| 350BV12-300 | 32.60 | 10-250 | 0-300 | 0-1.2 | 45-160 | -0.095 | 250 | 350 |

| 400BV12-400 | 50.40 | 10-250 | 0-400 | 0-1.2 | 55-200 | -0.095 | 350 | 400 |

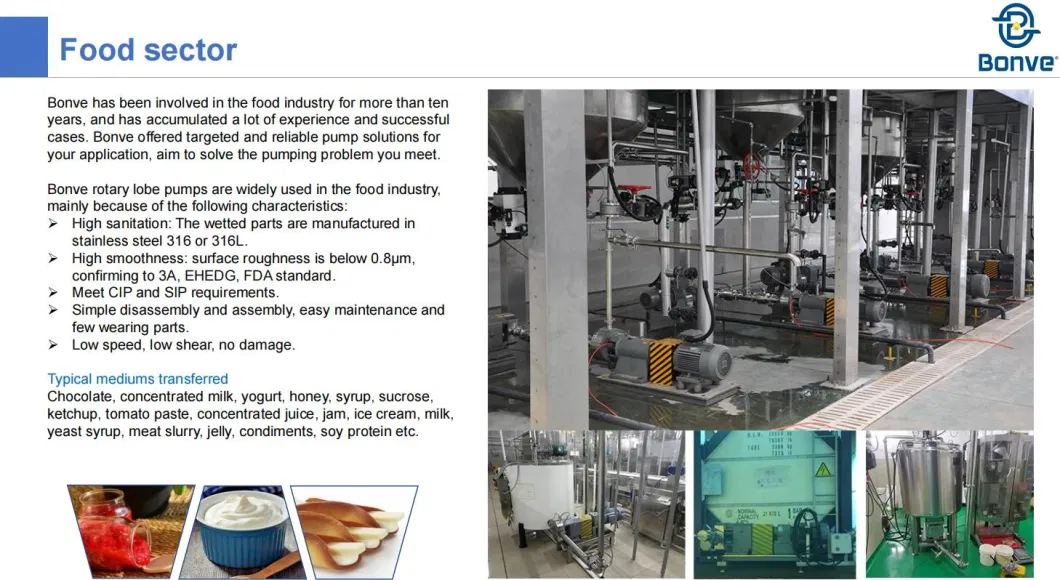

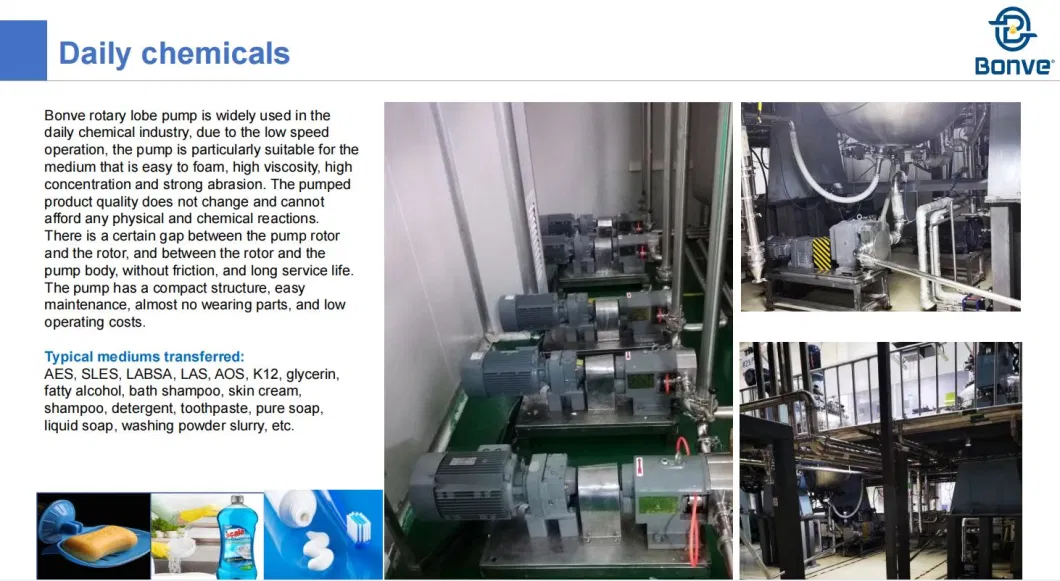

Applications and site photos

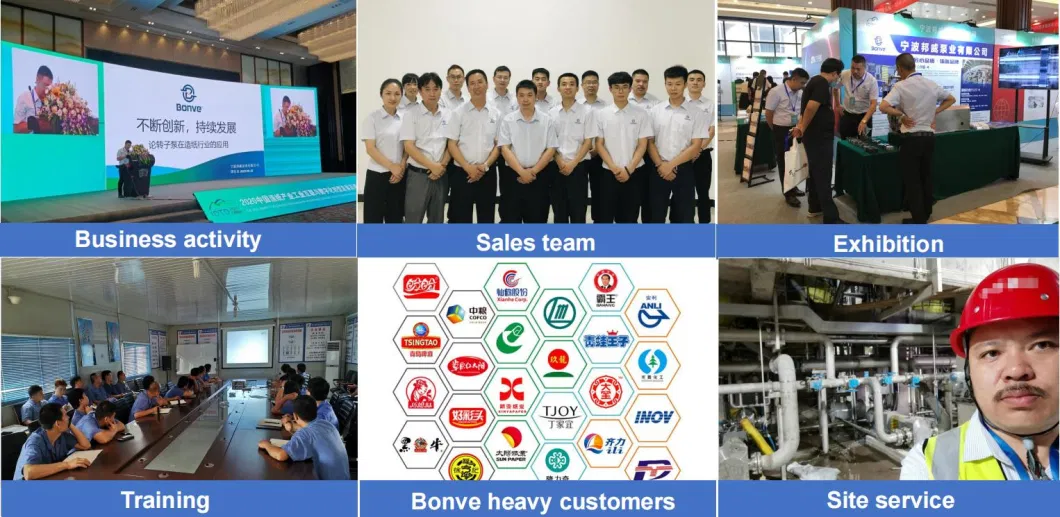

BONVE is a Chinese leading manufacturer in ROTARY LOBE PUMPS and HOMOGENIZER MIXERS, ISO9001:2015 approved company. Providing its customers with customized pumping and mixing solutions and solving their problems during the production. Bonve has more than 20 years of expertise and technical know how. We design, R&D and produce. When you choose a Bonve pump, you not only get the high quality pumps, but you also get the advantage of Bonve's engineering expertise and years of application knowledge in the food, chemical, pharmaceutical, cosmetics industries etc.By 2022, we have obtained more than 30 patents, such as invention patents, utility model patents. Owns one set of full automatically pump testing system, 98 sets of advanced CNC machines, including mills, borers, lathes, drillers, grinders, machining centers etc. and a variety of precise inspection equipment.Bonve pumps are acknowledged and used over 40 countries around the world. By 2022, more than 5000 companies used Bonve pumps and over 60000 units pumps are running in the world. Time and again companies specify Bonve Pumps as the "standard" equipment for their manufacturing processes. We are looking forward to be partner with you.

How guarantee the supplied pump is the best choice?

--To ensure satisfactory performance of pump, it is important that the pump must be properly selected firstly. We select the pump according to your characteristics of medium and condition of the technological requirements, bring you the right pump for your critical process.--With more than 21 years (2001-2022) industry experience, offering rich and actual solution. Pumps we sold out has been over 600,000units running in the world.--Customers we served from various industries more than 5,000 including food, beverages, daily chemicals, pharmacy, pulp and paper, coating and painting, oil and gas, biotechnology etc.

How you control quality?

--Organized control to select and evaluate of our vendors.--Incoming inspection for all the raw meterails.--Quality process controla. Raw material inspectionb. Process spare parts according to approved drawingsc. Assemble the pump based on customs using conditiond. Test pump's performance (record flow rate, discharge pressure,current and temperature)e. Inspecting conformity--All the pump main parts are processed by CNC maching, high-precision fabrication

What is your Warranty?

We guarantees that the pumps supplied are of high quality and reliability. Warranty is 18 months from the date of manufacturing. If any quality problem, we will send you the parts without cost in 3 working days.

How to operate your pump properly?

We have the complete English manual, training file and vedios to guide how to install the pump, how to maintain pump.